When we bought an SLA resin 3D printer, we found that the printed model was not the same as we imagined, or even did not print the model successfully. The first thing that comes to people’s mind is the problem of machine. In fact, the preparation before printing and the operation of the printer are also very important and will largely affect the results of the model. Even for entry-level SLA 3D printers, using them requires some basic knowledge and operating skills. In this guide, I will talk about some influencing factors beyond the machine, as well as how to use SLA 3D printers, what are the common usage problems and precautions. I hope this tutorial will help you to print models successfully with SLA resin printer.

Preparation Before Using SLA 3D Printer: Model Slicing

3D Printing is an additive manufacturing technology. SLA 3D Printing needs to cure the resin layer by layer, realize the shape of each layer, and finally manufacture the entire solid body of the model. In this process, how dose the printer control the solidified shape and the movement of building plate layer be layer? The 3D model file we need for 3D printing is in STL format, which means Standard Triangle Language or Standard Tessellation Language. Slicing is to convert the STL model into a set of instructions that the SLA 3D printer can accept. This is a critical step in successfully printing your model. The effect and quality of SLA printing are affected by slicing. Different print qualities can also be achieved by setting sliced files.

Model Slicing Notes For SLA 3D Printer

- It is best to choose the smooth side of the hem. It is best to have no holes

- Do not choose the largest contact surface close to the back plate

- Bottom rise 5 mm, select all supports

- Check some insecure supports

- Multiple supports must be added close to the bottom plate for full support. Supports that are too thin may crash during the model printing process.

Material of SLA 3D Printing

Resin is a material suitable for rapid prototyping. Capable of providing hard and delicate prints. The advantage is that the resin printed model will be smoother than the FDM printing, has a good surface finish, and hardly needs sanding. But the troublesome point is that after all resins are printed, they need to be treated with high-concentration alcohol.

Preparation of Resin Notes For SLA 3D Printing

- Choose resin: In order to prevent damage to the printer, it is recommended to use high-quality resin materials, which are safe and can provide better printing results.

- Take resin: Before using photosensitive resin, please shake the container gently.

- Use resin: Do not let the skin touch the photosensitive resin directly. If it causes skin irritation or discomfort, rinse with water immediately. It is best to wear gloves the entire time you work with the resin.

- Conservation of resin: Resin can be poured back into the container after use. Photosensitive resin needs to avoid direct sunlight and strong light, and prevent to dust from entering.

How to Print Model with SLA 3D Printer

When we finish preparing the model and materials, the next step is to import the resin into the tank and connect the USB stick to the printer. After we close the top cover of the SLA printer, we only need to select the model file and run the machine, what we need more is to wait for the model to be completed. But usually the process is not that easy, especially for these people who try SLA printing for the first time. The following suggestions will provide some useful information to help you.

Machine configuration: Do not place the local around flammable and explosive substances or heat sources, place the local in a ventilated, cool and less dusty environment.

Power socket: the power plug must be connected to a 3-hole socket with a ground wire. During the installation, do not apply other products power cord instead, but apply the additional power cord of the machine.

Machine placement environment: Do not place the light-curing 3D printer in an environment with high vibration or instability. Machine shaking will hinder the printer print quality.

Fixed position check: Before printing, the fixed position of the handle and slot on the platform must be stuck tightly to prevent instability when printing.

Screen survey check: Before applying the machine, please make sure the screen lighting is normal and wear sunscreen glasses. Do not look directly into the eyes when testing the screen.

Check the exposure time: When printing, please make sure the exposure time is within the specified range of the resin. If the print time exposure is too much, the model will expand or the time is too little, thus avoiding forming the shape. Different machines, model size, and support are all parameters that hinder the exposure time, so generally customers who just started light-curing 3D printer can first ask professional technicians to understand the range of parameters. Then, I want to test the results of the print. Change the parameters of the appropriate model printing accordingly.

Best Budget SLA Printer 2022

If you want to pick a SLA 3D printer suitable for beginners and expect it to have a friendly price, then Anycubic Photon Mono 4K is the best choice. It is equipped with a 6.23-inch LCD screen, which can achieve 4K high resolution and meet the exquisite printing effect of miniature models. The printing volume of 165x132x80mm (1.74L) can meet the needs of ordinary resin model printing.

Among the budget resin printers under $200, machine configuration of Anycubic Photon Mono 4K stands out, its cost performance is very high. Using an LCD-based SLA 3D printer also comes with the replacement cost of the screen, which is expensive. So in order to improve durability of printer, Anycubic Photon Mono 4K added a dedicated and replaceable anti-scratch film above the screen, making the expensive screen more durable than competitors.

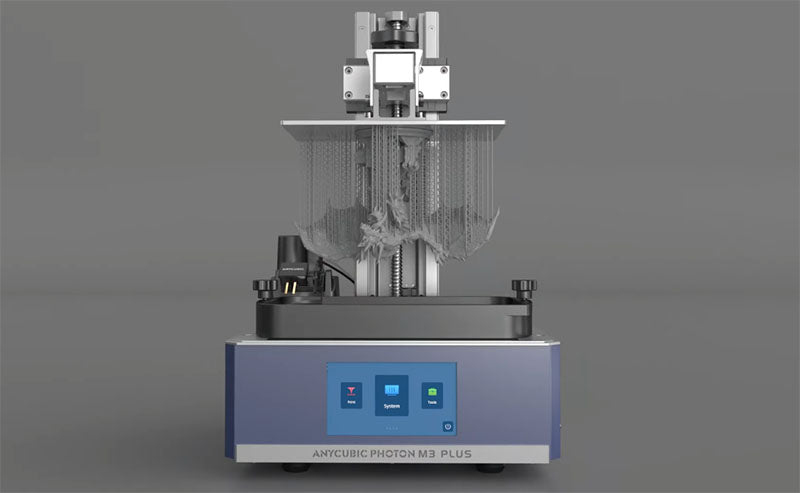

Of course, if you prefer large size printers, we can recommend Anycubic Photon M3 Plus to you. This large format resin printer has also been upgraded in terms of resolution. It has the print volume of 245 x 197 x 122 mm and is equipped with a 9.25-inch 6K monochrome screen, which is more professional and improves the printing experience of 3D printing enthusiasts.