Video

Effortless Intelligent Printing

Anycubic filaments are equipped with the Intelligent Identification Filament system for optimal printing efficiency when paired with ACE Pro. It automatically recognizes printing information to achieve a convenient and intelligent printing process.

*The Intelligent Identification Filament function requires an internet connection and must be used with Anycubic filaments that support the Intelligent Identification Filament system.

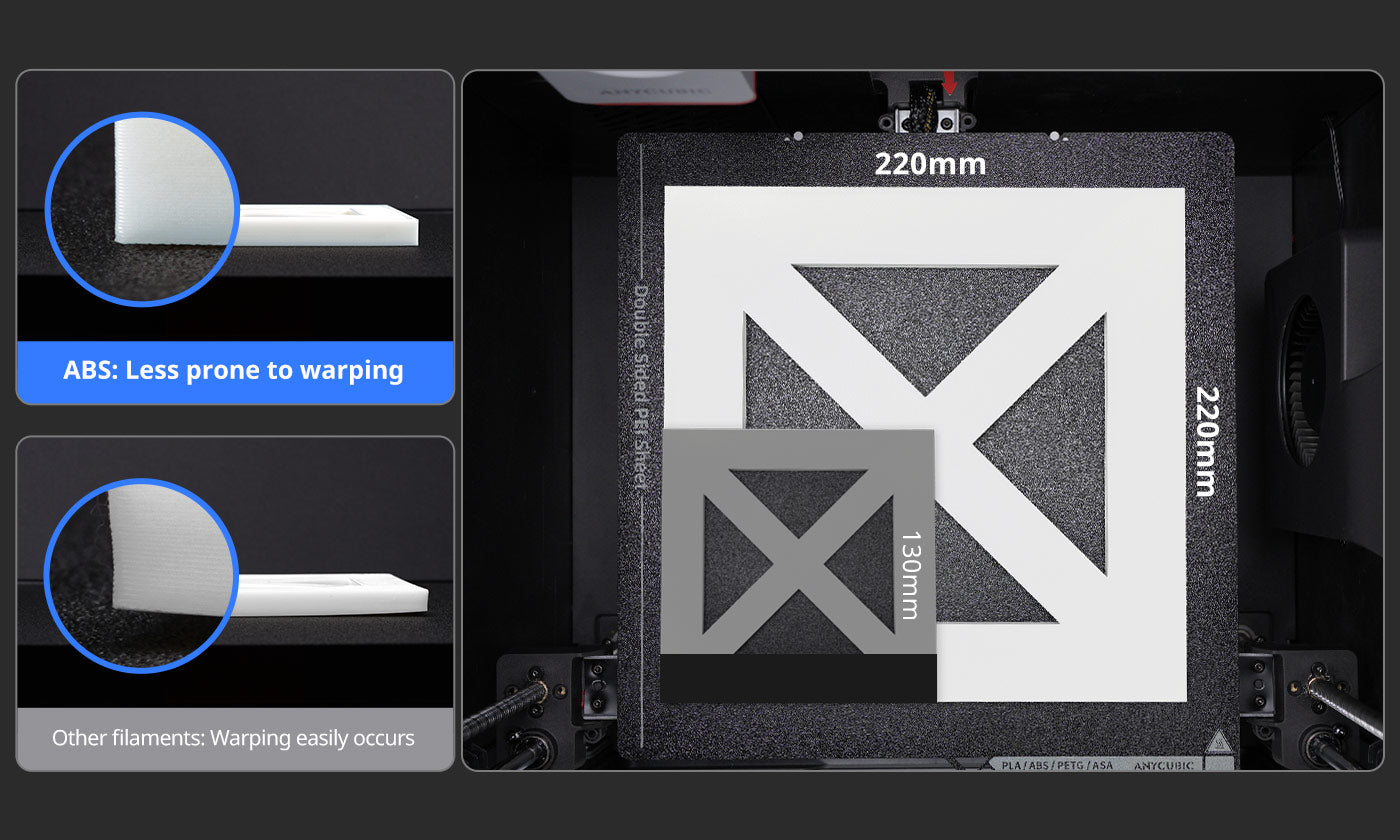

Optimized Anti-Warping Property, ABS Full-Bed Printing Made Easy

Anycubic ABS offers superior printability by minimizing warping caused by thermal stress during the printing process. It enables a 220mm × 220mm anti-warping print area with a heated bed at 100°C.

Superior Impact Resistance: Various Applications

Anycubic ABS delivers superior impact resistance for intricate auto components and appliance chassis, maintaining structural integrity under stress.

High-temperature Resistance

Anycubic ABS filament maintains model durability, form, and strength even in environments up to 85°C. ABS maintains model integrity and resists deformation under high temperatures.