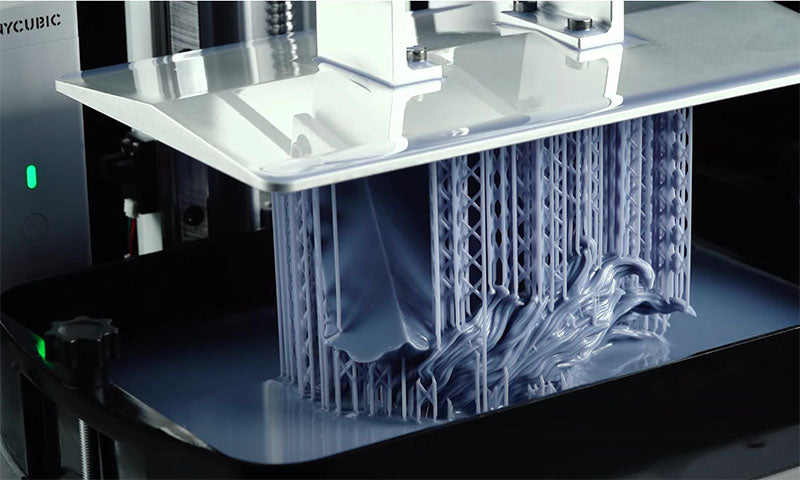

3D printing is the process of printing a 3D digital model into a physical object by means of a 3D printer. The digital model then involves the slicing process. Without support, those overhanging parts or tilted models cannot be printed, so we often need to add support to the model in this slicing step in order to ensure the success of 3D printing. Before printing, we need to consider adding the support, and after printing, we need to remove the support that is not part of the model itself. This tutorial will cover 3D printing supports, why we need them and how to add supports, especially to help us solve the problem of support removal.

What are Supports in 3D Printing?

The support is not part of the model you are going to print, but it greatly affects the outcome of the printed model. Because 3D printing is a layer-by-layer or point-by-point additive manufacturing process, supports will help the printer to build the model in specific locations. With supports, 3D printing is able to go further in building almost any shape and movement, only to remove it after the model is completed. But the addition and removal of supports are also challenges for the 3D printing enthusiasts, especially for beginners.

Supports For FDM Printing: FDM printing is fused deposition 3D printing, which requires printing out a model layer by layer based on a slice file. When there is no overhanging part of the model, there is no need for a support structure to assist in the printing process. Each point on each layer can be used as a support for a higher layer. Many models with regular shapes are simpler to print, especially with FDM printing. If no support is needed, then the model removed from the print bed with little additional post-processing is an ideal piece.

Photo source: Simplify3D

Supports For Resin Printing: FDM and SLA printers have different characteristics, FDM printing is usually large but relatively simple structure, the shape is also relatively regular model, so in many cases do not need to add support. Detail is the most prominent advantage of SLA printing. For SLA, it is usually necessary to print models that are also more delicate, with complex structures and more irregular shapes. For example, the role model of the limbs, vivid movements usually need support to assist in completing the print, handheld weapons also obviously have suspension or cross-bridge structure, before slicing the model, there are many parts that need to add support.

Why Does 3D Printing Need Support?

If the steps of adding and printing support are missing, it is obvious that the printed model will be defective, or even that the printer will be able to finish printing successfully. Then the model will be interrupted in the part where the support is missing, and the printer will run but not be able to continue building the model.

When is a Support Structure Required?

When we discuss supports of 3D printing, we usually refer to the parts of overhang. Slicing software has special settings to mark overhangs and add supports. The slicing software used by many people is Cura. If you are going to use a resin 3D printer, another more professional slicing software is CHITUBOX.

If the vertical angle of an overhang is less than 45 degrees, this overhang can be printed without support. The 3D printer has a small horizontal offset on a plane stacked layer by layer. A layer is stacked on top of a smaller offset, rather than completely on top the previous layer. In this way, the 3D printer can print overhangs with a smaller vertical tilt. All overhangs below 45 degrees can be supported by the previous layer. Typically, 45 degrees is considered the critical angle. If the verticality, is less than 45 degrees, no support is needed. However, everyone’s situation is different and depends mainly on the performance of the printer, both the performance of the printer and the material you are using.

A good machine and high quality filament can improve the success rate of printing, the quality of printed models, and reduce some unnecessary and troublesome problems in the printing process. For enthusiasts who want to choose a great resin printer, Anycubic Photon M3 Premium is the new choice for desktop resin printers, also is the one of the most cost-effective options , with 8K high resolution and large build volume of 250*123*219 mm.

Different Types of Support Structures

Tree Support: Tree support is a tree-like structure that can be used to support the overhang parts of the model. This type of 3D printed support is only attached to certain positioning points of the overhang. The advantage of a tree support is that it can be removed more easily without destroying too much of the overhang's bottom surface. However, we need to note that it is only suitable for non-planar overhangs, such as nose tips and hand movements of figure models, arches on architectural models, etc. On flat surfaces, tree bracing does not provide sufficient stability.

Photo source: Tutorial video for 3D Printing Tree Supports

Normal Support: The type of support commonly used for 3D printing. This type of support is composed of vertical columns, some of which are connected to the entire space. Such a support is suitable for almost all overhanging parts. However, it is more difficult to remove it and it is likely to damage the surface of the model.

How to Remove 3D Printing Supports

First, observe the support structure below, where it is easy to come down without the cover, and try to break the support with your fingers. Try to be as gentle as possible. If done correctly, most supports should come off very easily.

3D printing support removal tools: sharp-nosed pliers, scraper or carving knife. People have different opinions about which tools are best. You can choose one of them to use, of course you can also use a combination. When using a knife of scraper, you can heat the blade properly. This way the support is easier to remove. You can use a small butane gun, but be sure not to damage the model. Many people do not recommend using a carving knife because it is sharp and can easily damage the model. After moving the support, sandpaper is a great sanding tool and the post-processing will make your model more perfect and refined.

Once an FDM print is complete, the model can often be removed directly from the build platform. However, resin printing requires additional processing, soaking the printed model in high-concentration ethanol. Anycubic Wash & Cure Machine 2.0 is a good choice. Closed washing in the machine can prevent the cleaning agent from splashing, which is more safe and protective. Washing and curing can improve the performance of materials, appropriate processing will make the printed model more prominent in the details it should be. After cleaning and curing, the support of the model can be easily removed, and the simple post-processing makes the model more ideal.