When printing with PLA in 3D printing, there can be issues with the PLA not sticking to the build plate. In the process of many users trying to print, the melted material was taken away by the moving nozzle, PLA not sticking to the bed, and even the first layer could not be built. In such cases, it is necessary to make appropriate adjustments and experiments until the best printing effect is achieved. So, we have collected four most commonly used methods, which can help you quickly solve the problem of PLA adhesion of FDM printers.

Why is PLA Not Sticking to the Bed?

Before discussing the solution, you may wonder why PLA does not stick to the bed. Is it because the hot bed is not flat? Or is the printing temperature too low? The following are common causes of PLA not sticking to print bed, which can also help to effectively troubleshooting PLA printing.

- Inadequate bed leveling and calibration

- Poor print bed surface quality

- Incorrect print temperature

- Insufficient adhesion of the first layer

How to Resolve PLA Not Sticking to the Bed

Solution 1: Adjust the distance between the nozzle and the heated bed

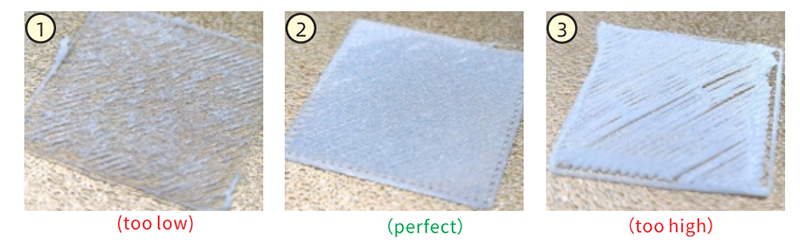

If the distance between the nozzle and the heated bed is too high, the PLA material may not adhere to the bed properly. First make sure your print is leveled, then adjust the Z offset value of the printer. When the distance between the nozzle and the print bed is correct, the printing effect will be improved. The situation is shown in the figure below:

|

Nozzle (Z offset) |

Too close |

Too high |

|

Characteristics |

The first layer will have obvious excess material protrusions, be almost transparent, or not extrude any material at all. |

The material cannot completely adhere to the bed, and there will be visible gaps between the extruded material from the nozzle. |

|

Issues and Risks |

The printer head may get clogged, the 3D prints will be difficult to remove, and the print bed may be damaged. |

During the printing process, the material will not stick to the bed, causing the 3D prints to warp or, after a period of time, causing the material to accumulate near the printer head, posing a safety hazard. |

Solution 2: Adjust the heated bed temperature

PLA requires a heated print bed to ensure material adhesion. If the temperature of the print bed is too low, the PLA may not stick to the bed. So we need to make sure the bed temperature is set correctly for PLA printing. When the PLA does not stick to the bed, try to increasing the temperature, usually between 50-70°C is recommended.

Solution 3: Use solid glue (PVP)

The adhesion of the print bed surface itself is also important. Consider using a PEI-coated build plate, or using a special 3D printing adhesive on the bed. Applying a layer of solid glue (PVP) on the printing surface can help the bed improve adhesion and avoid the problem of PLA not sticking to the bed.

PEI coating ensures excellent adhesion to the print bed and enhances the success rate of printing. Anycubic Kobra 2 Neo equipped with a PEI-coated spring steel platform is recommended, and it also features automatic leveling to provide convenience to the machine. The printing size of Anycubic Kobra 2 Neo is 220*220*250mm, which provides excellent printing quality and smooth printing experience, making it cost-effective among entry-level printers.

Solution 4: Clean the heated bed

Before printing, ensure that the hot bed surface is clean and free of dust or residue. Use a low concentration of alcohol or water to wipe and clean the surface. Making sure the print surface is clean can prevent problems with PLA adhesion.

![Troubleshooting Guide: PLA Not Sticking to Bed [4 Methods to Resolve it]](http://store.anycubic.com/cdn/shop/articles/pla-not-sticking-to-bed.jpg?v=1683770006&width=1100)